Air fryers have taken American kitchens by storm, offering a healthier way to indulge in crispy, delicious meals. But have you ever wondered what makes your food slide off so easily or how the device withstands scorching temperatures? The answer lies in the unsung hero of every air fryer: its interior coating.

What Are Air Fryer Coatings?

Air fryer coatings are specialized layers applied to the interior basket and walls to prevent food from sticking. These coatings ensure even cooking, easy cleaning, and safe usage, all while enhancing the appliance’s lifespan. Without them, your air fryer would be little more than a fancy toaster.

Why Do Coatings Matter?

Think of the coating as the armor of the air fryer. It protects the metal surface from food residue and corrosion. Moreover, coatings ensure you’re not spending hours scrubbing burnt-on grease – a win-win for convenience and hygiene.

A Quick History Lesson

Non-stick coatings aren’t new. They date back to the 1930s when PTFE, also known as Teflon, was discovered. Over the decades, innovations like ceramic coatings have added more eco-friendly and durable options. These advancements have significantly influenced air fryer design.

What’s in the Coating?

- PTFE: The industry favorite for its slipperiness and heat resistance. It’s the reason your fries don’t cling to the basket.

- Ceramic Coatings: A natural alternative that’s free from synthetic chemicals like PFOA and PFAS. It’s gaining traction among eco-conscious consumers.

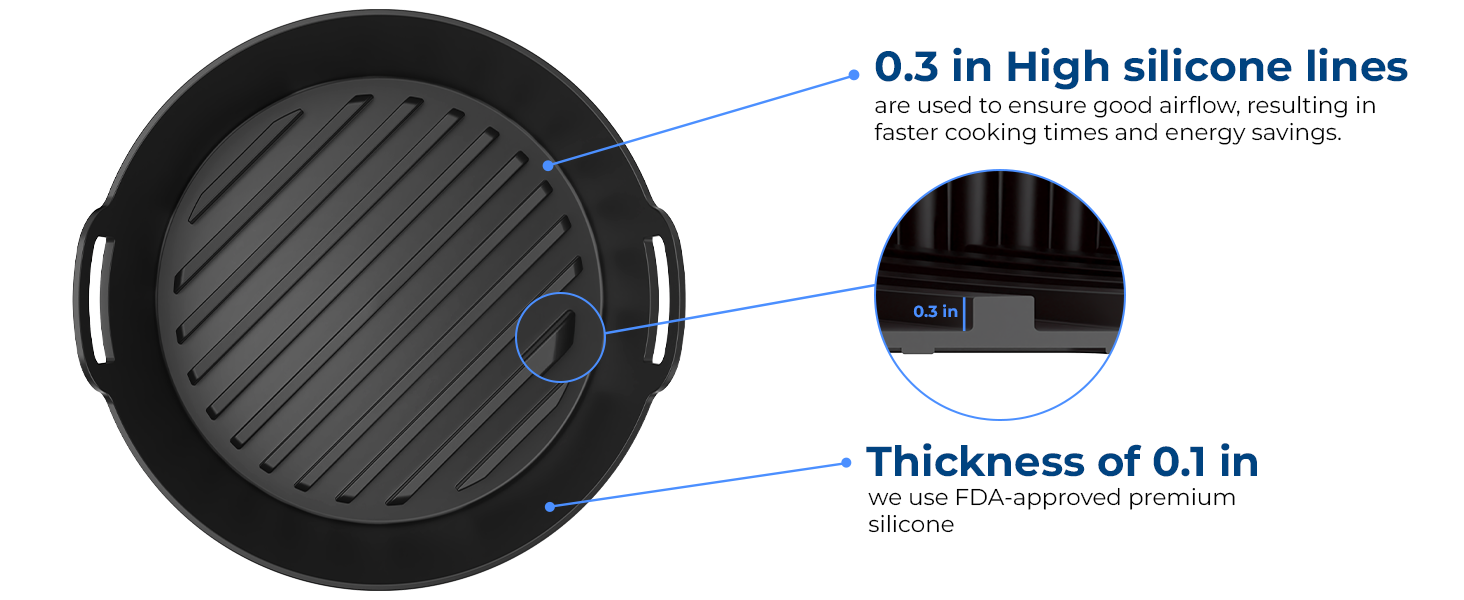

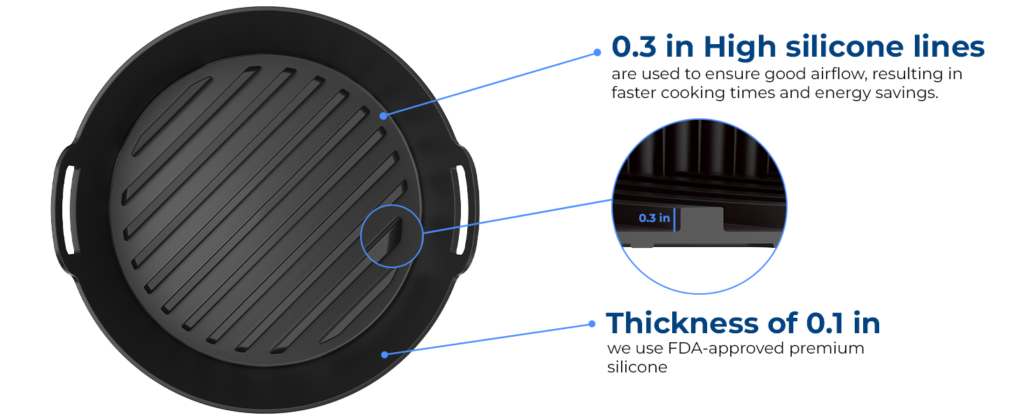

- Others: Materials like silicone and enamel offer niche solutions, often found in premium or specialized models.

Who Supplies These Coatings?

Big players like Chemours (for Teflon) and Whitford dominate the market. Ceramic materials often come from companies like Ilag or Greblon. These suppliers work closely with air fryer manufacturers to meet safety and performance standards.

How Are Coatings Applied?

The process is a mix of science and artistry. Manufacturers either spray or dip-coat the material, then bake it at high temperatures to bond it to the metal. Some are experimenting with plasma spray technologies to improve durability.

Performance Metrics That Matter

Good coatings must handle temperatures exceeding 400°F without breaking a sweat. They also need to resist scratches from utensils and frequent washing. These attributes are tested rigorously before products hit the shelves.

Testing Standards

To meet U.S. regulations, air fryer coatings must pass food safety certifications like FDA and LFGB. Manufacturers also simulate years of use in testing labs to ensure the coatings hold up.

What About the Environment?

There’s growing concern over the environmental impact of synthetic coatings. PFOA, once common in non-stick materials, has been phased out due to toxicity. Many brands now tout PFOA-free certifications and explore greener alternatives like bio-ceramic coatings.

Challenges with Coatings

No coating is perfect. Frequent use, abrasive cleaners, and metal utensils can cause peeling or wear. While ceramic options are eco-friendly, they tend to chip more easily than PTFE.

The Upside of High-Quality Coatings

Investing in a well-coated air fryer means better cooking results and less maintenance. Think of it as buying peace of mind – no more worrying about uneven heating or stuck-on messes.

Brand Case Studies

- Philips: Known for PTFE coatings with exceptional durability.

- Ninja: Combines PTFE and ceramic to balance performance and eco-friendliness.

- Cosori: Focuses on FDA-approved coatings with a reputation for easy cleaning.

The Future of Coatings

What’s next? Researchers are exploring graphene-based coatings for unparalleled heat distribution and durability. Meanwhile, bio-based materials could make air fryers even more sustainable.

Conclusion

Interior coatings might not be the star of the show, but they’re the backbone of every air fryer. With continuous innovation and a focus on safety, the future looks promising for this essential kitchen technology.

FAQs

1. What is the safest air fryer coating?

Ceramic coatings are often considered the safest due to their natural composition and absence of synthetic chemicals like PFOA.

2. How can I prevent my air fryer’s coating from peeling?

Avoid using metal utensils, abrasive cleaners, or high-temperature dishwashing. Hand-washing is your best bet.

3. Are PFOA-free coatings safe?

Yes, PFOA-free coatings, such as modern PTFE or ceramic, are tested rigorously for safety and performance.

4. How do I know if my air fryer’s coating is FDA-approved?

Look for labels or product descriptions that specify FDA compliance. Most reputable brands highlight this feature.

5. Are there eco-friendly air fryer coatings?

Absolutely! Ceramic and bio-based coatings are gaining popularity for their environmental benefits.